We help people repair plastic

Recreate Missing Piece on a Bumper Cover

Occasionally, you may have a bumper cover that has a missing piece. A new, aftermarket, or reconditioned bumper cover may not be available leaving you no other option but to recreate the missing piece.

Video

Step-by-Step Instructions

Step 1

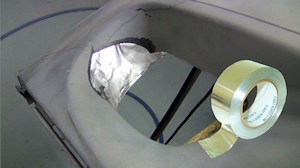

On this particular bumper cover, a chunk of the fog light hole is missing and must be recreated. The outline shows approximately what must be created.

Step 2

As usual, you will need to clean the area with a Polyvance plastic cleaner.

Step 3

Taper into the void with a die grinder and a tapered burr.

Step 4

Create a temporary backing with some thick, heavy-duty, aluminum foil tape .

Step 5

With the Nitrogen Plastic Welder, cover the temporary backing to fill the void. Make multiple passes until the thickness of the new material closely matches the thickness of the surrounding bumper plastic. Smooth out the plastic with the airless plastic welder.

Step 6

Allow the plastic to cool, peel off the aluminum tape, and add more plastic to the opposite side and smooth it out with the airless plastic welder.

Step 7

Shape the plastic with sanders, grinders, knives, files and other tools that you have to get the profile the way you want it.

Step 8

Apply Flex Filler, allow it to cure and sand it smooth.

Step 9

Spray with primer and it is ready to top coat. Compare the "before" and "after". It may not be perfect, but it’s better than it was, and unless you knew where the damage was, you would never notice.

Products Suggestions